Why Use Fibers from Finite Fiber?

Our customers enjoy lower costs when switching to Finite Fiber engineered fibers. Often, these savings are found in the process by reducing cycle times. Others have seen improvement in waste reduction due to increased green strength in unvulcanized sheeting. Still more have found that fiber simply costs less than fabric reinforcement.

Our application specialists are constantly looking for opportunities to find bigger profits for our customers by improving their product to the point where their customers are willing pay a higher price. When we help you improve the effectiveness, durability and/or efficiency that your customers demand, they will deliver a better product for their customers. This quality cycle starts with just a little fiber.

We are no longer simply replacing old leather belts with tire cord remnants. We are creating new, exciting polymer compounds with truly sophisticated chemistry. We can do what others can't so you can do what you have always needed. We will help you every step of the way.

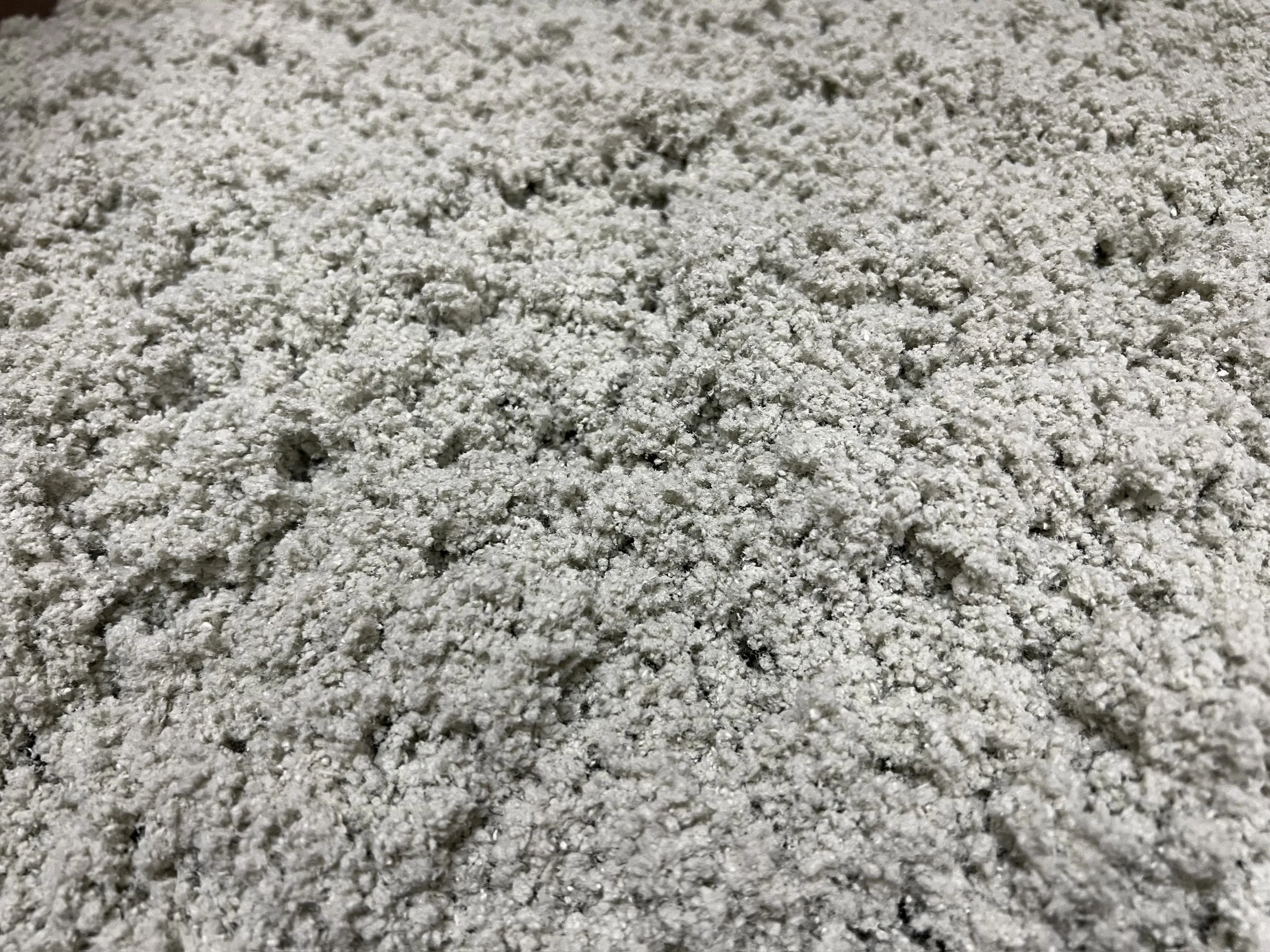

70x Magnification of Aramid Dispersion

Fiber Basics

The utilization of natural fibers as a reinforcement in rubber compounds has been around for nearly 100 years. The early fibers were created from tire cord remnants. Today's fiber additives are available in a wide range of chemical structures (glass, organic, synthetic, aramid, carbon, coated and uncoated); as well as various diameters, bundles, twists, fibrillation, and lengths. Fibers offer unique compound properties such as increased tensile modulus, abrasion resistance, improved tear strength, noise reduction, thermal stability and cut resistance. The fiber's crystallinity, decomposition temperature and polarity impact the ability of the fiber to adhere to the polymer matrix and enhance cured elastomer compound performance. These characteristics also impact the ease of dispersion in the uncured elastomer compound. The rod-like structures can be oriented in "with-grain" to provide unique directional properties or anisotropy. Finite Fiber's technical team will assist you in achieving real performance enhancements. We will identify the fiber type and length, advise on any formulation adjustments necessary and recommend any production changes which might be necessary to insure your compound is delivering the highest performance possible. PelleFiber is a patent pending product that creates fiber bundles which can include bonding agents and dispersion aids, in a high density pelletized form that is versatile, accurate and easy-dosing in the processing operation.

Fiber Types

Micronized or Flock Fibers - Aramid and Carbon Fiber

Generally, between 100 micron and 2mm in length. Milled and screened to control length.

Precision Cut - Cotton and Nylon

Individual fibrils typically cut to a tight tolerance - usually 3mm or greater in length.

RFL Coated Cord Bundles Fibers - Polyester and Nylon

1mm - 11mm lengths are common. The easy-to-handle bundles contain hundreds, even thousands, of individual filaments. The filaments separate under the shear stress of standard mixing equipment producing a highly dispersed fiber reinforcement.

Pulp or Fibrillated Fibers - Aramid

Fibrillated fibers are usually 1mm long. They have a larger surface area and a branch structure which aids in the mechanical bonding to the rubber matrix.

Blended Fibers - A Combination of Fibers

All of these fibers can be blended to create the polymer matrix that will produce the best physical properties for your product. Our patented Varamix® product is a prime example of this customization.

Properties

Fiber Load Ratios

Anisotropic Properties

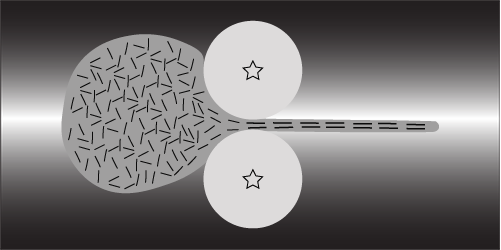

The use of engineered fibers provides additional opportunities to manipulate polymer properties. This is accomplished with the creation of fiber directionality. Specifically, modulous can be altered significantly by aligning the fibers in a common direction in the milling, calendering and extrusion processes.

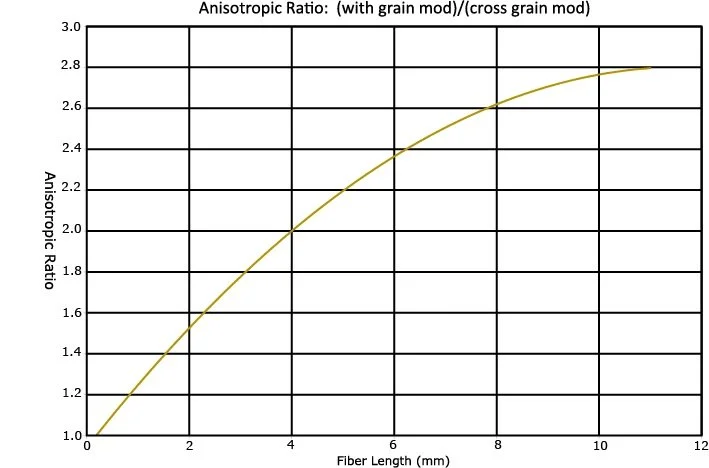

Longer fibers, randomly oriented, create more tensile modulus (strength). In the case of oriented fibers, more modulus is realized in the "machine direction" (with the grain) of the polymer matrix. See anisotropic chart above.

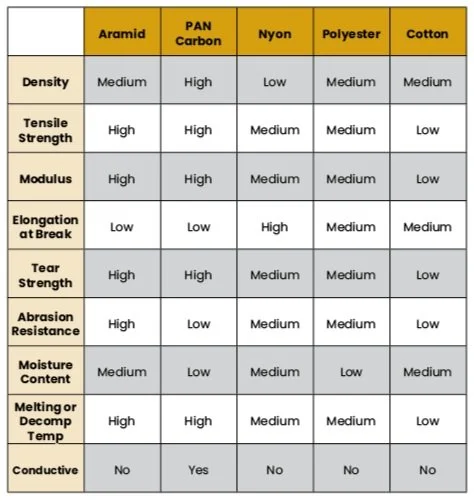

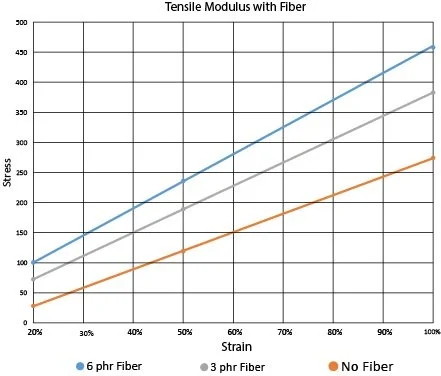

The ultimate result of every fiber reinforcement project is to manipulate the basic properties of polymers to produce the highest performance compound for your specific application. The first chart provides general property characteristics for each of the major fibers. The second chart is an example of how dramatically tensile modulus can be improved with the introduction of fiber. Other properties can be influenced with equal results.

Milling and Calendaring

Extrusion

Effects of Fiber Length

Aramid

Aramid fiber is a dry processed engineered fibril which has a high-heat and high-strength properties making it a practical choice in a variety of extreme application environments.

PAN Carbon

PAN Carbon fibers are lightweight, have high dimensional stability, are chemical and biological resistant, and are ideal for rubber and plastics reinforcement.

Our Products

Cotton

Spun and treated denim cotton textile fibers offer the highest physical properties and are physically superior to fill and warp thread blends in cotton reinforcement application.

Polyester

High tensile Polyester has dimensional stability at high temperatures, high breaking strengths, is excellent in resisting mildes and acids, ages well, and has resistance to stretching.

LInks and image scroll feature to be added on 4/8 and 4/9. Will also reorder products to match current website - FS

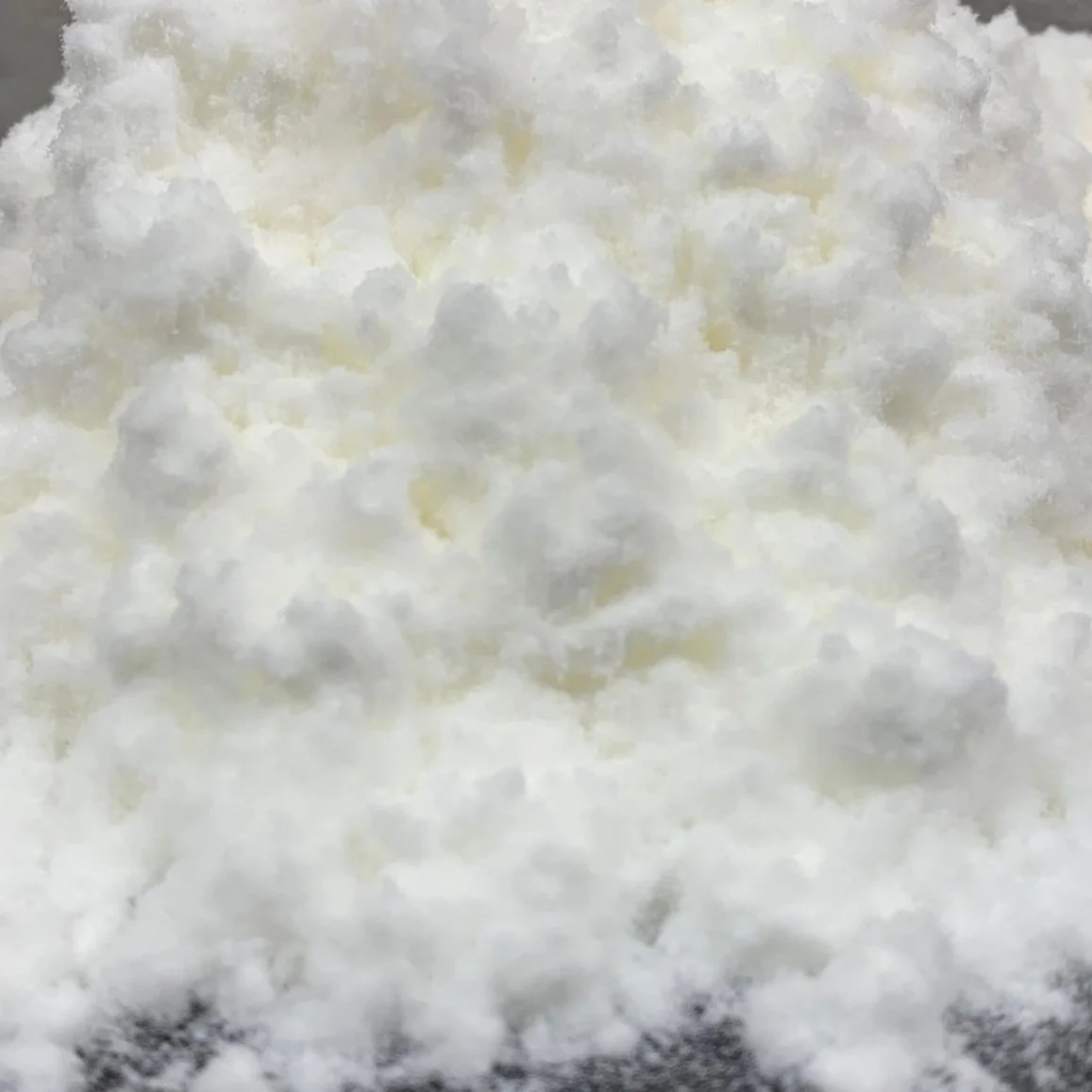

PuriCel

100% natural cellulose fibers for filtration, metal working coolant, building material additives, chemical and processing aids, pool and spa filtration and liquid spill absorbent (PurAbsorb).

Nylon

Nylon is dimensionally stable, has a high melting point, high tensile strength, resists abrasion, is chemically stable, tear and cut strength and light weight perfect for compression and extrusion.

Varamix

Varamix® Aramid Fiber blend is a patented product which uses Kevlar®, Twaron®, and Technora®. Varamix is a 100% fiber product and has a highly crystalline polymer chain.

PelleFiber

PelleFiber® is a patent pending, pelletized form for versatile, accurate, easy-dosing of fibers and pulps in processing rubber and thermoplastic compounds. 100% customizable.